April maker challenge 21- RFID mouse

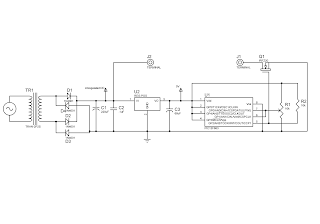

I got started late on the AMC, so I'm a few behind. I have, however, managed to average one a day since the 10th. I'm offline at home until May 6 (moved- why do I NEVER remember to arrange things like that ahead of time?), so I'll post my last one now. I have a ton of others, so I'll trickle them out, because I enjoy this, but this'll be it for the daily do. I'd like to include an RFID reader in a mouse. I think it's doable- some computer mice are pretty large, and by hacking ruthlessly at a hub and RFID reader, you should be able to do it easily enough. Why, you might ask? Quite simply, it would be a good way to keep your PC secure. Workplace hijinks can occasionally cause heartburn, so I know several coworkers who lock their PC when away from their desks. I'd prefer to have it lock itself after 2 minutes of no action, then have it automagically unlock when I get back to my desk. Thus, an RFID reader that detects a tag I have in a ring I wear an